Galv360 Coating for Marine Chain Applications

Ever since steel has become widely used, people have been inventing ways to prevent corrosion and abrasion in order to make it last longer. In fact, corrosion costs the U.S. economy an estimated $300 billion per year (about 3% of GDP).

Hot-dip galvanizing (HDG) has been in use as a method of corrosion protection for iron and steel since the 18th century. Hot-dip galvanizing creates a zinc layer on the part surface by immersing the steel in molten zinc at over 800 degrees Fahrenheit.

In marine environments, the zinc layer provides a sacrificial coating on the steel surface that, when exposed to salt water and sea air, forms what is known as white rust. This white rust actually helps prolong the life of the chain by preventing red corrosion from destroying the material.

It’s logical to think that the thicker the zinc layer, the better protected the chain. That was true—until a new coating called Galv360Ⓡ was introduced and quickly started becoming the standard for many marine applications.

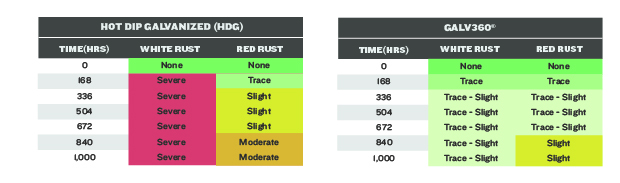

Salt Spray Test: Galv360 vs. hot-dip Galvanizing

To find out how Galv360 stacked up against traditional HDG, we partnered with an independent testing company, Assured Testing Services. Our partners conducted a 1,000-hour salt spray test to compare the performance of the finishes. Here’s what they found:

While both coatings lasted through the entire 1,000 hours of the test, the third-party testing partner concluded that v showed the least amount of corrosion degradation for both white and red rust.

The HDG chain showed slight red rust after 336 hours, while it took 840 hours for the Galv360 chain to reach a similar state. At 672 hours, HDG began showing moderate red rust, while Galv360 did not reach this point during the entire length of the test period.

Thicker Coating ≠ Better Performance

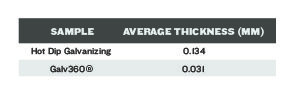

Common wisdom in the industry is that a thicker zinc coating usually means a longer-lasting chain. Galv360 performed better in our test than HDG, even with an outer layer that was ¼ of the thickness! Our third-party tester measured both samples prior to the salt spray test, and found the following results:

Impressive performance, to be sure. But why does thickness matter? The thickness of the Galv360 layer can be more precisely controlled than HDG, which results in a more uniform and controlled end wire diameter and chain size. Galv360 also does not display the typical thickness variations or sharp edges of HDG. And finally, Galv360 can help ensure you hit your coating tolerance requirements, even with tight specifications.

Galv360 is Becoming the Standard in Marine Chain

The U.S. military is leading the charge in specifying Galv360 for demanding marine chain applications. The U.S. Navy equips its hovercraft with grade 120, Galv360 coated chain. These hovercraft operate in what is known as the Navy’s most corrosive environment. The U.S. Army also recently retrofitted its landing craft with Galv360 coated anchor chains and bow chains.

Not only does Galv360 outperform HDG by lasting longer, it is more environmentally friendly. Nontoxic and heavy metal free, Galv360 is also becoming widely regarded as the “green” solution for corrosion prevention.

Get On the Cutting Edge of Steel Protection in Marine

When you upgrade from HDG to Galv360, you’ll get a longer life out of your marine chain for your toughest, most demanding applications. Your team at Laclede Chain can help you make the switch. Contact us today to learn more about the benefits of Galv360!